Plasti-Fab

EPS Product Solutions

EPS or GPS for Insulated Roofing Applications – How Do You Choose?

When you embark on a roofing project, there are many layers (literally) to your project. Selecting the right insulation to meet your goals is one of them. So when you evaluate the type of insulation you require, it is important to measure what matters. Cost, R-value, thickness, on-time deliveries, and design flexibility of your insulation are just a few factors taken into consideration.

At Plasti-Fab, we have different products to choose from ranging from EPS Type 1 insulation, higher compressive resistant products like PlastiSpan 20, 25, 30, 40 and even 60, and then our EnerSpan® product line (GPS), manufactured with Neopor graphite bead. So let’s take a look at how you choose between EPS insulation and GPS insulation for your project.

When to use EPS insulation for your roofing project

EPS insulation has long been the go-to product of choice for residential and commercial roofing contractors due to its design flexibility, best cost per R-value, long-term thermal resistance, and large product offering.

According to Professional Roofing Magazine, “Roofing contractors who use EPS for their insulation layer are able to achieve higher R-values with fewer EPS layers, reducing labor time and cost. … Built-up roof (BUR) systems: To taper or increase the slope of an existing low-slope roof, using EPS can reduce insulation costs up to 30 percent compared with other rigid foam insulations.”

As EPS insulation offers the highest R-value per dollar, many building professionals choose it for their roof insulation needs. For those who specify EPS for its cost effectiveness, moisture performance and stable long-term R-values, product options are available that reduce costs even further.

While roof insulation is required by code, and as a practical necessity, it doesn’t have to break the bank. Readily available EPS insulation options can help you save money on commercial roof jobs, in both new construction and building retrofits.

SBC Magazine

When to use GPS insulation for your roofing project

Before we get into the option of using Graphite Polystyrene, first lets talk about exactly what this option is. GPS is a Expanded polystyrene product that has been manufactured using Neopor graphite bead (made by BASF). The result is a silver grey foam that provides an R-value of 4.7 per inch. While various EPS insulations range from R3.75 per inch up to 4.27 per inch, the Neopor based product enhances your R-value per inch, allowing for a thinner insulation layer in your project.

GPS is a great insulation solution for your roofing project when you require a higher R-value but are limited to your thicknesses of the insulation layer. Like EPS, the graphite enhanced EPS maintains its R-value for the life of the product, so the R-value you install will never diminish over time like other insulation options.

Because GPS is manufactured the same way as our expanded polystyrene, you have the same flexibility in your design for thickness, tapered or sloped insulation as needed. Our staff of roofing experts can assist you in the development of the designs for your project. Or if you are looking for a simple solution for flat roofing material, you can order the GPS in a variety of thicknesses to meet your project goals.

In the end, both options are a good solution for roofing insulation. The use of Neopor in the EPS simply provides you with a wider range of potential solutions to achieve the roofing insulation you require.

Click here to learn more about our EnerSpan® insulation (GPS).

The Importance of Roofing Insulation for your Home or Commercial Building

No matter where you live, it is important to maintain a comfortable temperature for your home or commercial building by ensuring the installation and maintenance of insulation. Proper insulation in the structure is important to establish a thermal envelope for the most effective energy efficiency. This month, we will be looking at roofing insulation and the different solutions for this application.

Your roof’s insulation acts like a protective blanket. It is wedged between the roof’s surface and the roof deck and is used to reduce the transfer of heat. A structure will experience approximately 25% heat loss through an un-insulated roof.

The Benefits of Roofing Insulation

A properly insulated roof will reduce your utility costs due to the R-value of the insulation you choose. However, there are many more reasons as to why insulation will truly be a benefit.

• Increased fire rating

• Lessened carbon “footprint”

• Mold resistance in EPS insulation

• Reduced condensation inside the building

• Less roof deck expansion and contraction from having a consistent temperature

The first rule of building performance is that heat moves from warm to cold. By insulating the your attic spaces or roof deck, you are creating a thermal barrier that helps eliminate that heat loss. When you consider that heat rises, insulating your roof is integral to maintaining your interior temperatures.

Not only does insulating your roof reduce heat loss, but it also helps you with moisture control in your structure. Similar to heat, moisture also moves from warm to cold. So interior warm moisture can cause problems at the roof line when it hits an un-insulated surface, creating potential for mold issues. Avoid these potential issues with properly insulated roofs and attic spaces.

Coming up

Stay tuned as we cover the various types of roof insulating applications for both residential and commercial construction in this month’s series. You will learn about the various types of commercial roofing assemblies and how Plasti-Fab’s EPS or our graphite-enhanced GPS is used to complete a building’s thermal envelope.

We will be looking at both new construction and renovation solutions, and how to select a product that best suits your home or building’s needs.

For more information on roofing applications for residential applications, check out our Residential Solutions.

For information on commercial roofing assemblies and the use of EPS and GPS, check out our Commercial Solutions.

What Sets Us Apart: Building with The Advantage ICF system

Insulating concrete forms are not a new concept for the building industry. However, there are some features that set each manufacturer apart from one another. Besides our dedication to Quality, Service & Expertise, we have 4 key features that set the product apart from the rest in the industry, creating a better building product that meets the needs of not only the homeowner but the builders that work with them.

Insulating concrete forms are not a new concept for the building industry. However, there are some features that set each manufacturer apart from one another. Besides our dedication to Quality, Service & Expertise, we have 4 key features that set the product apart from the rest in the industry, creating a better building product that meets the needs of not only the homeowner but the builders that work with them.

Click HERE to view “The Anatomy of an Advantage ICF Block”

1. Patented Interlock Design

The Advantage ICF Systems patented tongue and groove interlock design on the horizontal joints allow tight nesting of the blocks. The groove on the bottom edge of EPS panels interlocks with the tongue on the top edge of EPS panels making it easier to apply a consistent even bead of foam adhesive in critical areas to interlock the blocks tightly. This eliminates the need for internal metal hooks that

interrupt concrete flow during placement or interfere with internal mechanical vibration essential for proper concrete consolidation as recommended by the Portland Cement Association to avoid voids in ICF walls (see PCA Bulletin RD134 “Concrete Consolidation and Potential for Voids in ICF Wall”).

The Advantage ICF System tongue and groove interlock design provide an additional barrier for moisture migration through the horizontal seams.

2. T abs to keep attachment surfaces aligned

abs to keep attachment surfaces aligned

The Advantage ICF System is the only ICF product that features tabs within the horizontal interlock design. Advantage ICF block internal webs tie the monolithic EPS insulation panels in place and provide 1 ½” wide attachment surfaces for your interior and exterior finishes. Tabs incorporated into the tongue on the top edge of the EPS panels slip into grooves on the bottom edge of the row above to keep the webs aligned making attachment of finishes easier and faster.

There are some areas where the tabs may have to be removed due to project-specific installation issues. This is done with little effort with the horizontal tongue and groove interlock between blocks maintained. This interlocking feature means less waste than reversible ICF Blocks.

Watch “How it Works” to see the animated installation of our Advantage ICFs

3. Easy to find Markings

An embossed line on the exterior surface of EPS pan¬els marks the middle of the 1 ½” wide vertical attachment surfaces on internal webs making it easy to find the surfaces for fastening interior and exterior finishes. All Advantage ICF System blocks are also marked with a vertical recessed c ut line every inch to facilitate cutting blocks to length when required.

ut line every inch to facilitate cutting blocks to length when required.

“Because this was our first ICF home, it was a bit of an unknown at the beginning. Advantage provided us with on-site support and training and once we got into a bit, everything worked well. I’m very comfortable working with ICFs now, it’s really a breeze—light, clean, and easy to handle.”

4. Brick Ledge Block

The Advantage ICF System Brick Ledge Block features a continuous uninterrupted concrete ledge. When brick ledge blocks are included in any ICF system horizontal steel reinforcement and stirrups are required in the concrete ledge portion to support loads. The Advantage ICF Brick Ledge Block features a web unique to the ICF industry that is molded into the EPS panel that forms the brick ledge. Attachment surfaces on internal webs within the EPS panel are consistent to the top of the ledge for easier fastening of required exterior finish materials to, a benefit only provided by the Advantage ICF Brick Ledge Block.

This superi or design of the Advantage ICF Brick Ledge Block allows it to be used to provide uniform support for cladding such as brick or stone and can also be used for support of interior or exterior concrete slabs. All concrete reinforcement is totally encapsulated within the concrete so it is not exposed to moisture which can lead to long term deterioration through corrosion. This is a significant improvement over other ICF designs that use EPS haunches molded into one face of the EPS panel. These haunches are considered structural voids and do not allow the steel reinforcement to be protected from moisture.

or design of the Advantage ICF Brick Ledge Block allows it to be used to provide uniform support for cladding such as brick or stone and can also be used for support of interior or exterior concrete slabs. All concrete reinforcement is totally encapsulated within the concrete so it is not exposed to moisture which can lead to long term deterioration through corrosion. This is a significant improvement over other ICF designs that use EPS haunches molded into one face of the EPS panel. These haunches are considered structural voids and do not allow the steel reinforcement to be protected from moisture.

Check out the full product lines available in both 6 and 8 inches here

An added bonus to building with the Advantage ICF product is the peace of mind you get, knowing it has a GreenGuard GOLD certification status. It’s not only a green product, but the company works to maintain the highest standards of sustainability in product and practice. To learn more about the sustainability initiative, visit www.pfbsustainability.com

Advantage ICF System for Below and Above-Grade Walls

The energy-efficiency of any building product is important when constructing a home or commercial building. Regardless of what product you select, it will have to perform to a standard of expectation that saves money when heating and cooling the space. At Plasti-Fab, we have a variety of different solutions for your insulation needs, but this week we will look to one of the building systems from Plasti-Fab: The Advantage ICF System®.

Walls built with the Advantage ICF System provide improved energy efficiency that results in reduced operating costs for the life of the building. In addition, since less energy is consumed, related greenhouse gas emissions are proportionately reduced. Today, more than ever, building an energy-efficient structure is the right environmental choice and will provide savings in energy costs. So why not continue your high quality, energy-efficient ICF basement up through the whole house.

A home built using the Advantage ICF System will make a wall structure more energy-efficient and significantly reduce the energy loss compared to a conventional new home constructed using wood stud framing and batt insulation. (The conventional home does not include any Plastispan like Melissa described in the previous blogs.) The graph below provides a comparison of the effective R-value for a wall assembly constructed using the Advantage ICF System versus a wood frame system with R-20 insulation.

Unintentional air leakage can be one of the biggest sources of heat loss in many buildings. Air leakage rates vary widely for different types of construction methods. For example, a 3,900 square foot home (similar to the one shown) using the Advantage ICF System for both above and below-grade walls was tested for airtightness in comparison to energy-efficient design requirements. The air leakage rate was found to be 0.22 air changes per hour indicating a very airtight structure. This confirms that the solid, continuous insulation wall construction provided by the Advantage ICF System will result in a significant reduction in air leakage versus other types of wall construction.

When building your whole house with ICF you increase the R-value and decrease the air leakage of your home. Builders and homeowners alike ask me all the time what is the best furnace upgrade they should put in there new ICF house. My response is, “Why would you spend lots of money on a furnace that will never run?”

For more information on Advantage ICFs, visit http://www.advantageicf.com

Experience the Strength & Security of the Advantage ICF System

Advantage ICF System® – Seabrook Island, South Carolina, USA

As hurricanes are becoming more of a regular expectation along the southern coastline, homes are being built to withstand these forces of nature. This southern Carolina homeowner turned to the Advantage ICF System to provide the strength and security for his coastal home. “We took our Seabrook design, with traditional stick framing, and modified it to withstand the forces of nature as this house was to be built right on the water,” said Eason. “The owner wanted to be sure that they had enough structure to handle the wind and water loads that typical hurricanes with wind and tidal surges could produce, and meet applicable building codes.”

As hurricanes are becoming more of a regular expectation along the southern coastline, homes are being built to withstand these forces of nature. This southern Carolina homeowner turned to the Advantage ICF System to provide the strength and security for his coastal home. “We took our Seabrook design, with traditional stick framing, and modified it to withstand the forces of nature as this house was to be built right on the water,” said Eason. “The owner wanted to be sure that they had enough structure to handle the wind and water loads that typical hurricanes with wind and tidal surges could produce, and meet applicable building codes.”

Working with a structural engineer, Eason specified the Advantage ICF System® for the above grade walls. The Advantage ICF System delivers two continuous layers of expanded polystyrene insulation for exceptional energy efficiency, along with the strength and durability of reinforced concrete. Light gauge steel framing was used for the roof and interior walls.

Working with a structural engineer, Eason specified the Advantage ICF System® for the above grade walls. The Advantage ICF System delivers two continuous layers of expanded polystyrene insulation for exceptional energy efficiency, along with the strength and durability of reinforced concrete. Light gauge steel framing was used for the roof and interior walls.

“The Charleston summers are hot and humid,” said Eason. “ICF construction added greatly to the thermal protection for increased efficiency and comfort. The strength of the ICFs combined with the all steel framing is very important in hurricane prone areas. In this area you’ve got wind, water, heat and humidity—ICFs help mitigate all of that.”

Despite the home’s robust structure that is designed to withstand 140 mph winds, it retains the character of an authentic turn-of-the- century Charleston-style home.

“You can use a technology like ICFs and finish with a home that looks appropriate in the Charleston Lowcountry,” said Eason. “What’s behind the walls is very different than what you expect. It is very high-tech, energy-efficient, and it enhances the safety and durability of the house.”

“The home provides us with a great example of disaster-resistant and energy-efficient construction using the Advantage ICF System,” said Advantage ICF System Product Manager Greg Doren.

“The home provides us with a great example of disaster-resistant and energy-efficient construction using the Advantage ICF System,” said Advantage ICF System Product Manager Greg Doren.

For more information on the strength of ICFs and how to integrate them into your project, visit www.advantageicf.com

ICF Answers: Top questions about using Advantage ICFs in Commercial & Residential Construction

What is the R-value?

Normally the first question that comes up about the Advantage ICF System® deals with the R-value of the wall assembly. Whether you are above or below grade, insulation matters. The effective R-value of a wall formed with the Advantage ICF System is approximately R-23.

What goes inside the blocks?

First, the appropriate size and strength of rebar is placed in the blocks both horizontally and vertically. Concrete with a 100 -150 mm (4″ – 6″) slump to provide a minimum 20 MPa (2900 psi) concrete strength reinforced as per design requirements is then added to complete the wall system.

How high can I go with the Advantage ICF System?

The Advantage ICF System can be used to form 152 mm or 203 mm (6″ or 8”) thick reinforced concrete walls. Maximum wall heights will depend upon specific requirements of your application such as back-fill height and type of soil conditions for below grade walls or wind loads for above grade walls. Consult your Advantage ICF System representative for wall heights that may require specific engineering design input.

What are the benefits of using ICFs?

The Advantage ICF System® is an energy-efficient building product. Its popularity continues to grow as architects, specifiers, building contractors, and the public at large become familiar with the benefits of using Insulating Concrete Forming (ICF) systems in residential and commercial construction projects.

Advantage ICFs have a patented interlocking system along the top and bottom edges, which allows the blocks to securely connect together, much like kids’ Lego™ blocks. Reinforcing steel is placed on the plastic web connectors inside the block cavity which is then filled with concrete. After the concrete pour, the insulating EPS remains in place on both sides of the structure, providing a highly energy-efficient building envelope.

As a construction professional, there are multiple reasons to build with and utilize the Advantage ICF System®. Aside from the multiple features and benefits experienced by the homeowner, the Advantage ICF System® helps you accomplish your project goals as well.

Use the Advantage ICF System® to construct walls below and above grade. Providing superior effective thermal resistance (RSI/R-value) and reduced air leakage on all types of residential, commercial and institutional projects

Why choose Advantage ICFs over other brands?

Insulating concrete forms are not a new concept for the building industry. What sets us apart from the rest? Aside from the patented interlock design, easy tabs for marking and finishes, and a few other key product features, what sets us apart is our dedication to providing unparalleled Quality, Service, and Expertise. Take comfort in the strength and energy efficiency of our Advantage ICF System, and enjoy the peace of mind knowing our experience and quality of service will help you every step of the way.

Do you still have questions about using the Advantage ICF System in your next project?

Check out more on the web site: Advantageicf.com or call us today to talk to a technical sales representative at 1-888-446-5377.

7 Reasons Why Building with the Advantage ICF System Is the Way To Go

Any builder knows setting up concrete forms for a residential basement application can be a tedious and time consuming process. Not only that, once the foundation walls have been poured, you have to go back and take all those forms off the poured wall. Once those forms come off, with today’s Code basement insulation requirements now you have to insulate the exterior of the wall at the very least. There must be an easier way…..

Any builder knows setting up concrete forms for a residential basement application can be a tedious and time consuming process. Not only that, once the foundation walls have been poured, you have to go back and take all those forms off the poured wall. Once those forms come off, with today’s Code basement insulation requirements now you have to insulate the exterior of the wall at the very least. There must be an easier way…..

Imagine if you can stack up blocks that not only provide the forming for the concrete, but an internal and external layer of insulation comes built right in. No stripping forms, or heavy equipment required for lifting that comes with other concrete wall forming methods. Think of it as building walls like you may have done with Lego blocks when you were young. The blocks can be carried right into the hole by one guy, and it’s literally a system of measuring and placing those blocks in courses up to your desired wall height. If the wall is a length that is not divisible exactly by the length of each block, you can cut them to length with a hand saw, in about 2 minutes. (You know, to account for the measure twice cut once method) There are tabs at the top and bottom of each block to help with alignment and “lock” the blocks into place. (Hence the Lego analogy)

So what are the true benefits of building with the Advantage ICF System?

Lightweight forms provide stay-in place insulation for energy efficiency. Not only is the forming crew able to work quickly and efficiently with a lighter weight building material, but you only build it once. No more going back to remove the forms and insulate the perimeter. In the process, you are providing the homeowner with a higher level of energy-efficiency for their home.

Lightweight forms provide stay-in place insulation for energy efficiency. Not only is the forming crew able to work quickly and efficiently with a lighter weight building material, but you only build it once. No more going back to remove the forms and insulate the perimeter. In the process, you are providing the homeowner with a higher level of energy-efficiency for their home.- The Advantage ICF system has internal webs with 38 mm (1 ½ inch) wide flange surfaces provided for attachment of interior and exterior finishes. Depending on the thickness of the block, you have an attachment surface every 152 mm (6 inches) or 203 mm (8 inches). This helps your sub trades out by providing a consistent attachment surface that does not require concrete screws.

- Fast, year round construction. Advantage ICFs can be placed in extremely hot days (yep – we’ve been there) or even when the snow is flying (been there too). The foam is unaffected by the temperature change, and are much easier to handle in conditions made challenging by the weather.

- Advantage ICF blocks are dimensionally sized to coincide with standard lumber for window and door bucks, and top plate. Save time in your lumber cutting by only having to cut to length, and not order special widths or rip the lumber down, making the installation of the lumber much more time effective.

Allows use of internal vibrators to assure concrete consolidation. The combination of the foam strength, with the molded tie (cross web) spacing creates a strong forming system, allowing for the recommended internal vibration. Vibration ensures that your concrete is completely consolidated and eliminates the “honey-combing” effect inside the forms. You can be confident you have a monolithic concrete wall without gaps or weak points.

Allows use of internal vibrators to assure concrete consolidation. The combination of the foam strength, with the molded tie (cross web) spacing creates a strong forming system, allowing for the recommended internal vibration. Vibration ensures that your concrete is completely consolidated and eliminates the “honey-combing” effect inside the forms. You can be confident you have a monolithic concrete wall without gaps or weak points.- The Advantage ICF System provides the air and vapour barrier for wall area. You need to address air and vapour barrier system continuity issues at windows and other openings, but you do not apply a separate material to the ICF wall area. (Note – those internal ties are marked for you on the block in the form of a slightly recessed channel so you can see right where to attach your finishes)

- We provide excellent field support. In order to ensure you have the best experience possible for the installation of the Advantage ICF system, we have numerous resources from installation manuals, technical details, field guides, how-to videos, and if you have questions we have not addressed, we will happily talk to you about your specific needs

As you begin your planning for your next foundation, frost wall, landscape applications, above-grade wall system, or party walls, consider the benefits of the Advantage ICF System. Give us a call (888) 446-5377 or Start your project now

The Advantage ICF System® is an EPS Product Solutions from Plasti-Fab Ltd.

The Dirt on Under-slab and Perimeter Insulation Part 2

In our last post, we discussed the importance of insulating the perimeter of your foundation. Today, we will be talking about the insulation under your slab and why it is just as important as the rest of the building to complete the thermal envelope.

Most basements are built in direct contact with ground. Concrete will absorb moisture, like a sponge, and the result is an uncomfortable, musty living space. The additional water introduced into the home can also lead to mold issues.

The basement floor is also a place of heat loss in your home. The idea that heat always rises isn’t entirely true. Heat will flow toward relatively cooler places. If ground under the home is cooler than the basement temperature, which is the case in almost every climate year round, heat will naturally try to escape through the concrete slab.

Installing an insulation & vapor barrier between the concrete slab and the ground is the best practice in insulating basement floors. The insulation will help keep warm air in, and the vapor barrier will keep unwanted moisture out.

Plasti-Fab manufactures a variety of EPS product solutions to insulate below your slab. DuroFoam® Insulation, PlastiSpan® HD insulation, DuroSpan® GPS insulation, as well as the higher compressive resistance lines of Plastispan® 25, 30, 40 and even 60 psi.

Besides the comfort and moisture issues that insulating below your slab helps to alleviate, there is an additional health benefit to home as well. In recent years, an increased awareness of Radon gas and the need for mitigation systems have taken the building market by storm. Areas high in Radon gases are required to install these mitigation system for the health of the home and the occupants. Plasti-Fab has worked hand in hand with Radon Environmental to develop Radon Guard Insulation, a key component in Radon mitigation systems. If you are insulating below your slab, using the Radon Guard insulation adds the health benefit to the insulation that is already working hard to add comfort to your living space. Learn more about this system.

To learn more about insulating under your basement slab, take a look at our Application Solutions section of the Plastifab.com web site.

The Dirt on Under-slab and Perimeter Insulation Part 1

To many who have been loyal followers of our blogs for some time now, you may look at this post and think “This looks familiar.” And you would be correct. With July being under-slab and perimeter insulation month, we highlight the insulation solutions for those applications, and this article, along with the one following it, are jam-packed with great information on product solutions from Plasti-Fab. Enjoy the “Throwback Thursday” aspect of today’s blog, and maybe even use it as a refresher course in perimeter and under-slab insulation.

We are about to spend the next few weeks covered in dirt. That’s right – throw on your work boots and join us as we take you through the world of insulating below grade with under slab and perimeter insulation.

Last week we talked about the importance of insulating under your slab and around the perimeter of your foundation. Not only is R-value an important factor, but the compressive resistance of the insulation you select is just as important.

At Plasti-Fab, we have a variety of insulation products that you can choose to insulate your exterior foundation. PlastiSpan® HD insulation, DuroFoam® insulation, and higher compressive insulation boasting a psi of 25, 30, 40, and even 60 psi.

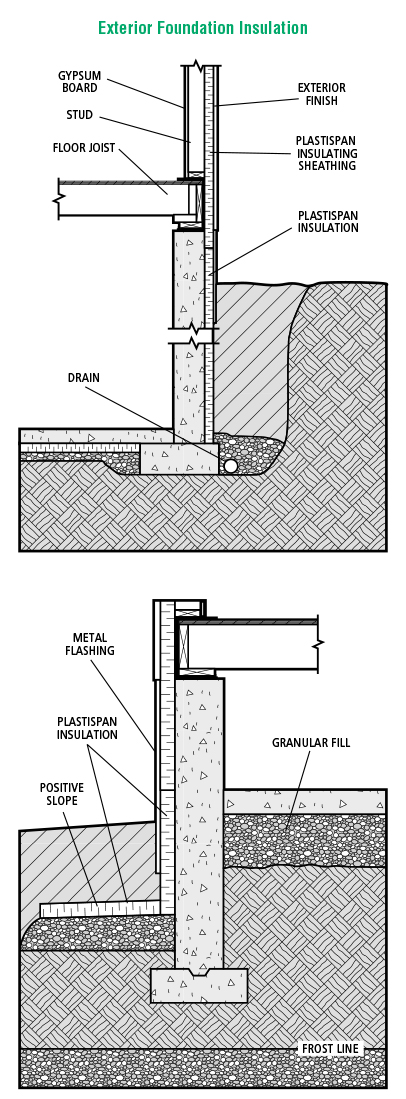

Following standard building practices, let’s begin with the perimeter of your foundation. Regardless of whether you have chosen a block or poured foundation, you will insulate the perimeter in the same method. The use of exterior foundation insulation reduces the likelihood of frost-heave under footings.

Insulating the exterior surface of the foundation wall provides the advantage of a fully insulated warm wall, which reduces the likelihood of degradation due to freeze thaw and of condensation forming on the inner face of the wall.

When a footing has to be placed above the frost line, external insulation can be adapted by placing it horizontally out from the foundation. This has the effect of raising the frost line to the level of the footing so there is no heaving of the foundation.Exterior foundation insulation isolates the foundation wall from outdoor temperature fluctuations, and provides a drainage plane which directs surface moisture to the drainage tile and protects foundation damp-proofing during back-filling.

With its outstanding resistance to moisture absorption, PlastiSpan insulation provides dependable long-term thermal performance when installed on the exterior face of the foundation wall.

What about drainage?

In most basement construction a drain is installed around the foundation at the footing level. The use of external insulation does not decrease the requirement for drainage. If there is concern that the drainage system may freeze, or that frost may get under the foundation, a horizontal insulation board, minimum 600 mm (24’’)wide, sloped away from the foundation, should be placed above the drain and the foundation.

To learn more about perimeter insulation for your basement/foundation walls, visit our application solutions page Insulating Exterior Foundations.

Homeowner heats up his basement with PlastiSpan HD Hydronic Insulation

Moving on with our under-slab insulation series, we are going to touch on Hydronic Insulation. Available in a variety of thicknesses, Plasti-Fab’s HD Hydronic Insulation provides the same comfort, energy-efficiency, and R-values you have come to expect, with the added benefit of channels sized specifically to fit hydronic tubing for radiant floor applications. No more tying the tubing down. Instead, simply snap the hydronic tubing into the pre-cut channels in the foam and you are ready to pour!

Moving on with our under-slab insulation series, we are going to touch on Hydronic Insulation. Available in a variety of thicknesses, Plasti-Fab’s HD Hydronic Insulation provides the same comfort, energy-efficiency, and R-values you have come to expect, with the added benefit of channels sized specifically to fit hydronic tubing for radiant floor applications. No more tying the tubing down. Instead, simply snap the hydronic tubing into the pre-cut channels in the foam and you are ready to pour!

Read on to learn how one Alberta resident used Hydronic Insulation to make his basement comfortable and energy-efficient.

Like most homeowners, Philippe Clairo disliked cold basements. So when he and his wife Cat Hackman had the chance to design a 2,300 sq. ft. custom residence, they went for a radiant heating system in the basement for complete comfort and energy performance.

“Coming from a house where our basement was always cold, we knew we wanted to heat the basement,” said Clairo. “I turned to Plasti-Fab and asked them if they had any products that could help us out.”

Plasti-Fab provided Clairo with PlastiSpan® HD hydronic insulation, a specialty product for radiant heating systems. The closed-cell rigid foam insulation is equipped as the first component in the radiant heating system to lessen heat loss beneath the floor system and provides uniform heat distribution. Unlike traditional radiant heating assemblies that depend on rebar and metal ties to affix the hydronic tubing, PlastiSpan HD hydronic insulation has pre-routed channels that hold tubing in place without any mechanical fasteners. Clairo, who saw the installation, observed the apparent advantage of PlastiSpan HD hydronic insulation over the traditional approach.

“With the floor installation, there was a little frustration from the trades at first, because they were not used to it,” he said. “But as soon as they got it, they installed it really fast. They said it took two hours instead of four to install the insulation.”

The efficiency of the radiant heating system backed by PlastiSpan HD hydronic insulation was paired with DuroFoam® insulation on below grade walls to produce a warm, comfortable basement that the whole family can enjoy. The lower level holds a recreation room, a small home theater, exercise area, and guest bedroom.

“In the basement, it is night and day with what we had before in terms of heat,” said Clairo. “Working with Plasti-Fab has been great,” he added. “The product was always on time, it was easy to install, and all the trades working here have been very impressed with it.”

Learn how you can use Plasti-Fab’s Hydronic Insulation for your home!