Plasti-Fab

EPS Product Solutions

Rebar Explained – A Comprehensive Guide to Rebar in ICFs

Posted on May 22, 2019 by Plasti-Fab

Compared to conventional foundation walls, ICFs require more rebar. However you can have a 6” thick concrete wall with ICF opposed to an 8” conventional foundation wall in most cases. Therefore the extra rebar can save you 2” of concrete throughout your foundation walls.

Since ICFs incorporate more rebar and are considered reinforced concrete walls, they will allow you to build a taller wall giving you a higher ceiling height compared to conventional concrete walls.

Rebar is used to solve structural design requirements related primarily to compression, tension and shear loads. Rebar will also control concrete shrinkage cracks.

Vertical Rebar in the Footing

Steel reinforcing dowels should extend a minimum of 40 times bar diameter in height from the top of the footing to match the size, spacing and position of the vertical reinforcement required in the foundation wall.

Concrete is strong under compression loads, but tensile strength is much lower. Rebar for below grade foundation walls with backfill on the exterior face is always installed in the inside third of the wall which is the tension side of the wall. For above grade or Party Wall applications the rebar is typically placed in the middle of the wall.

When you look in the Advantage ICF block you will see rebar clips on the plastic webs that space the 2 layers of EPS.

Horizontal Rebar in ICF Courses

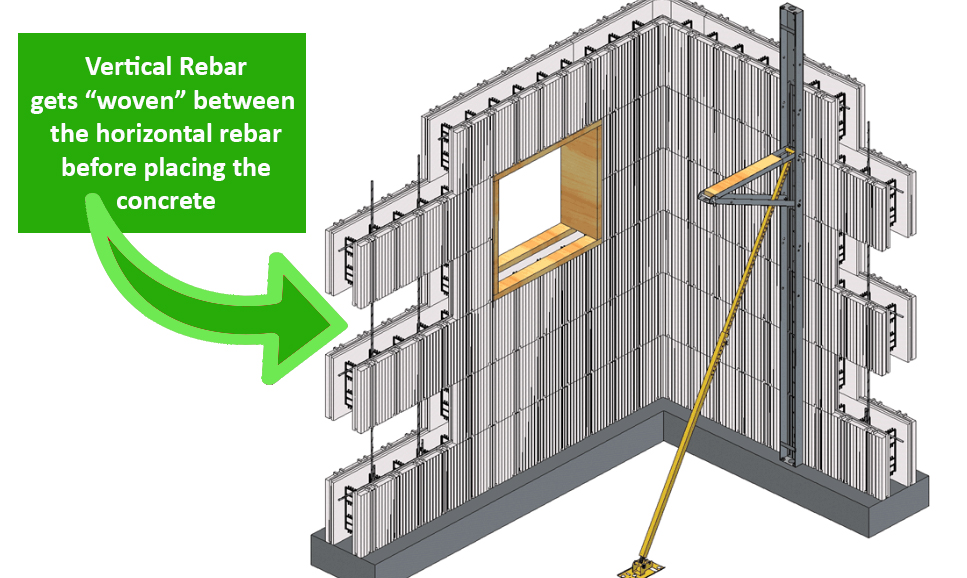

Once the first course of ICFs is complete, place rebar horizontally in the appropriate rebar clips in the web, following your engineering specifications (or the design tables in the Advantage ICF System Technical Manual). The horizontal rebar is staggered in order to allow the vertical rebar to be placed between the horizontal bars after all the courses are in place. For below grade ICF Walls install your horizontal rebar in clip #1 (the first inside rebar saddle) on the first row of block and #3 (the third rebar saddle) on the second row and alternating between #1 and #3 for all the sub sequential courses of block.

Rebar is typically on the tension side of the wall (or the inner third in most cases) However, for a more in-depth descriptions, see the Advantage ICF System Technical Manual.

Staggering the rebar from row to row creates a “weave” effect that enables the horizontal rebar to cage (another term “hold” works also) your vertical rebar in place. Vertical rebar is installed once the wall is at full height.

Install the specified vertical reinforcing steel by sliding it down between the offset lengths of horizontal rebar. This creates a ‘weave’ effect that enables the horizontal rebar to hold the vertical rebar in place.

Job site tips for rebar

● Make sure you know where on the job site you want the rebar unloaded.

● Keep the rebar as clean as possible from dirt and other contamination as this will affect the performance

● Cut 4 foot lengths and pre-bend them for corners and T-Walls

● Have a proper rebar cutter and bender on site or arrange to have this done for you prior to having the rebar delivered to achieve required tolerances.

● Place plastic caps over the top of vertical rebar sticking out of footings or walls to prevent injury from sharp ends .

You can click the following link to find out what rebar you will need for your job.

http://www.advantageicf.com/technical-library/technical-library.html

It is critical to review all applicable building codes and ICF manufacture’s engineering, technical manuals as well as Code Reports to understand the proper spacing and sizing requirements of rebar.

Resources

Advantage ICF Technical Manual

Advantage ICF Installation Manual

Advantage ICF System Checklist

If you have any questions about the rebar placement for your project, call us today at (888) 446-5377.

Category: Advantage ICF, Plasti-FabTags: concrete forms, foam blocks, how to place rebar in ICFs, how-to, icf, insulating concrete forming system, rebar, reinforcing steel

Thank you for your tip to keep the rebar as clean as possible so it doesn’t affect its performance. My brother has been thinking of starting his own construction company and we’ve been researching rebar together. I’ll be sure to pass this tip onto him so his future construction company runs well.

I found it interesting when you said that rebar is used to solve structural design requirements related primarily to compression, tension and shear loads. My uncle works in construction and he always answers my questions when I need to do something at home. It would be nice to know how my house was built and also to know how to fix a rebar structure if needed.

Why is a pony wall different when placing rebarr. It is below grade should the rebarr not be placed on the inside third of the form. Verses what your drawing calls for?

Your corner rebar placement could be slightly improved. It’s better to run your inside corner ells long and attach to the other side (with appropriate cover) in order to prevent spalling the inside corner. If design calls for 2 parallel bars, the change in material is miniscule, but greatly improves tensile strength of the corner.